Depot

Depot

Family Laundry: The World’s Most Advanced Managed EV Depot

In a industrial corner of Oakland, California, Family Laundry faced a challenge: how to transition to electric vehicles without disrupting daily operations. Their solution, powered by Port Power’s intelligent infrastructure, isn’t just another charging station—it’s a complete fleet operations platform that happens to also optimize energy costs.

Fleet Operations Come First

For Family Laundry, a commercial laundry service running daily delivery routes across Oakland, the question wasn’t whether EVs could save money. The math was clear: approximately $10,000 per vehicle per year in savings, even without government incentives. The real challenge was operational: how do you ensure every vehicle is charged and ready for its route without adding complexity, manual coordination, or operational risk?

Traditional charging infrastructure treats this as a hardware problem—install enough chargers, hope for the best. Port Power approached it as a fleet management problem that requires deep integration with how the business actually operates.

The system integrates directly with Family Laundry’s vehicle telematics, pulling real-time data on each vehicle’s state of charge, location, and usage patterns. When a driver returns from their route and plugs in, the Port Cloud platform immediately knows which vehicle it is, how much charge it has, and—critically—when it needs to leave for its next route the following morning.

This isn’t just monitoring; it’s predictive optimization. Each vehicle gets precisely the charging it needs, prioritized based on departure time and mission requirements, without anyone manually programming schedules or moving vehicles around. The result? Drivers park their vehicles and walk away. Everything else happens automatically. No shuffling vans at 2 AM. No morning surprises finding vehicles that didn’t charge. No complex scheduling spreadsheets. The fleet is just ready, every morning, exactly as needed.

From Cost Center to Profit Center

But Family Laundry discovered something even more valuable: their charging infrastructure could generate revenue.

The depot hosts multiple separate fleets, each with different vehicles, schedules, and operational requirements. This multi-tenant capability transforms the entire economic model of depot infrastructure. What was previously a capital expense that only benefited their own fleet now generates revenue from hosted tenants.

The genius of Port Power’s system is that multi-fleet operations require no additional operational overhead. License plate recognition (LPR) cameras automatically identify each vehicle as it arrives, instantly linking it to the correct fleet account. Access control happens invisibly—no cards, no apps, no check-in process. A driver from a tenant fleet simply plugs in, and the system handles everything else.

For the hosted fleets, this solves a massive problem. Small to medium-sized fleets often can’t justify building their own depot infrastructure—the capital costs, permitting complexity, and technical expertise required create insurmountable barriers. By hosting them, Family Laundry provides instant access to enterprise-grade charging infrastructure.

But managing multiple fleets with different needs and priorities could be operationally complex. This is where Port Power’s intelligent prioritization becomes crucial. The system understands that Family Laundry’s own vehicles get top priority—they’re the reason the depot exists. Tenant fleets receive charging based on their service tier agreements, available capacity, and their own departure schedules.

Behind the scenes, the Port Cloud platform tracks every charging session, categorized by fleet, vehicle, and time. Family Laundry receives detailed utilization reports showing exactly which vehicles charged when, for how long, and how much energy they consumed. This granular data enables accurate billing to tenant fleets while providing analytics about usage patterns that inform capacity planning.

Multi-Fleet Complexity Made Simple

Managing three separate fleets at one facility would typically require separate infrastructure, complex access controls, and significant manual coordination. Port Power’s approach makes it feel effortless.

When a vehicle plugs in, it might receive full power. When another arrives that needs to leave in 4 hours, the system might allocate more power to ensure it reaches the required charge level in time If power capacity is constrained, at the expense of vehicles that have more time to charge, or are lower priority.

This dynamic prioritization happens continuously, reassessing hundreds of times per night as vehicles plug in, reach target charge levels, or need boosted priority due to schedule changes. The system balances fairness to tenant fleets with priority for the host fleet, while ensuring every vehicle reaches its required charge level before departure.

The LPR system provides an additional operational benefit: parking enforcement. The cameras can detect when non-EV vehicles occupy charging spaces, when vehicles remain plugged in after charging completes, or when unauthorized vehicles attempt to use the facility. This automated enforcement ensures the infrastructure remains available for its intended purpose without requiring manual oversight.

For Family Laundry, this hosting capability has created a new revenue stream that substantially improves the return on their infrastructure investment. For the tenant fleets, they gain access to reliable, professionally managed charging infrastructure that would have been impossible to build independently. It’s a genuinely win-win arrangement enabled by intelligent software.

Energy Optimization: The Secondary Benefit

With fleet operations optimized, Port Power’s system turns to minimizing energy costs—and this is where the microgrid capabilities come into play.

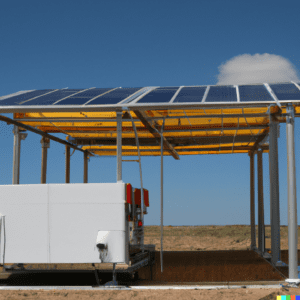

The facility features a 50 kW solar array and 233 kWh battery energy storage system (BESS) working in concert with the charging infrastructure. During the day, solar panels generate power that charges the battery. At night, that stored energy powers vehicle charging, supplemented by grid electricity only as needed.

But it’s more sophisticated than simple solar-plus-storage. The system performs real-time grid arbitrage, buying electricity when rates are low and discharging the battery during expensive peak periods. It shaves demand peaks that would trigger high utility charges. It coordinates solar generation, battery dispatch, building loads, and vehicle charging to minimize total energy costs across the entire facility.

This energy optimization happens as a background process, never interfering with fleet priorities. If vehicles need charging during an expensive rate period, they get charged—but the system draws from the battery first, minimizes grid usage, and staggers loads to avoid demand charges wherever possible.

The result is an 80% reduction in energy costs compared to unmanaged charging. For a depot supporting multiple fleets with dozens of vehicles, that’s many thousands of dollars per month in savings. These savings flow back to Family Laundry’s bottom line.

Built to Scale

The depot’s modular architecture using standardized PortSkids and PortPanels means expansion is straightforward. As Family Laundry adds more vehicles or takes on additional tenant fleets, they can add charging capacity or reconfigure the parking lots’ modular units—no redesign, no custom engineering.

The facility was implemented in two phases: first the charging infrastructure to get operations running, then the solar and storage systems to optimize energy costs. This phased approach allowed the fleet to start benefiting immediately while building toward the complete solution.

A New Model for Fleet Electrification

What makes the Family Laundry depot the world’s most advanced isn’t the hardware—it’s how the system prioritizes fleet operations above everything else. The technology exists to serve the business needs, not the other way around.

Fleets need reliable operations, not science projects. They need vehicles ready on time, every time. They need systems that work invisibly in the background. And increasingly, they need ways to offset infrastructure costs through shared utilization.

Port Power’s approach delivers all of this while also optimizing energy costs and enabling renewable integration. But those benefits come secondary to the primary mission: keeping fleets running smoothly.

As more urban delivery operations electrify, the Family Laundry model offers a template that works: fleet operations first, energy optimization second, and shared infrastructure to improve economics for everyone. That’s the future of managed depots, and it’s already operating in Oakland.